A history prepared on my memories of Hopkins Transport

"I have very few genuine pictures of actual Hopkins Transport Lorries, and most of the pictures are not in original H Hopkins & Sons colours. I have tried to find the closest equivalents that I can find on the Internet. However, what you will see in the images is representative.

Prepared and dedicated fondness and love from Grandad (Norman) to my grandson Thomas

June 2016"

Early Development prior to Grandad Hopkins’s death in 1944 (1940)

My brother Brian has done some research, and my cousin Robert has added some more data.

Grandfather Harry Hopkins was a sea captain from Cardiff in South Wales, plying the Bristol Channel with a sailing boat. He delivered coal to Bideford, and if the tides were wrong, he would have to wait for 12 hours for the next high tide to get over the sand bar at the entrance to the river Taw and Torridge estuaries, or he would unload his coal at Clovelly for onward shipment to Bideford by pony & trap. He was a regular visitor to Bideford, and ended up buying the Ring-o-Bells Hotel in Honestone Street.

Reported in March 1920 - At Monday's sitting of the Bideford Borough Magistrates, 17 year old youth was accused of and fined £1 for stealing an accumulator valued 36s, from a motor car, the property of his employer, Henry Hopkins, cab and motor car proprietor, of the New Ring of Bells Inn.

Along with the Hotel, there was a dairy, which would have required a pony & frap for delivering the milk. According to records Rob has, the Ring-o-Bells changed hands many times.

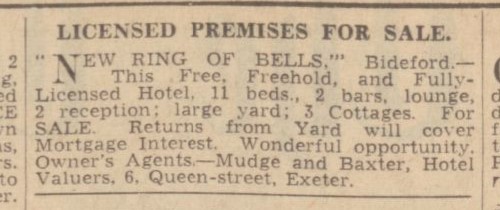

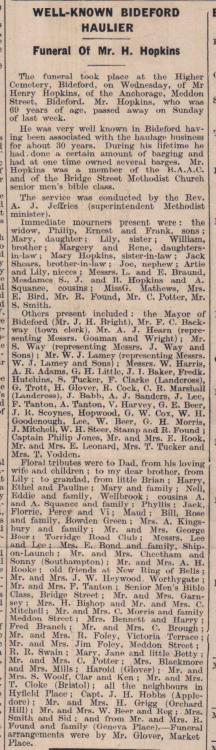

14 August 1937 - Western Morning News

Somewhere along the line, Harry married ---- Wilcox, who lived in Coldharbour Lane. She was a staunch Methodist, and would never have approved of drinking or gambling! Once he committed to living in Bideford, he became known for his entrepreneurial flare and my mother recalls how he used to visit the station as the LSWR trains arrived, and offer accommodation at his hotel. To do this, he used a pony and trap. Cousin Robert recalls that he owned a Model T Ford, and used it for a taxi service, and for touting for hotel business, but the Model T Ford did not start production in the UK until 1911 (the same year as my Dad was born), so Mum’s recollection of using the pony & frap could well be true. Mum also mentioned many times that Harry Hopkins was the first in Bideford to buy a new Ford for under £100 (may have been the Model T). Clovelly was an important port to him, and from the later years in the 1800’s, he started moving coal and herrings (in season).

The 1911 Census (2 April) details Henry Hopkins (bargeman and carriage proprietor) living at 56 Honestone Street.

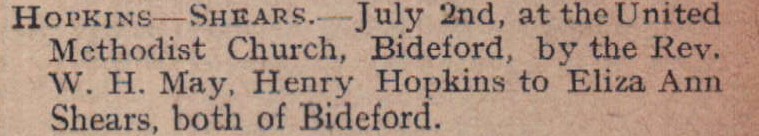

Eliza Ann Shears was born in Monkleigh in 1878 - her parents were Richard and Hannah - and in the 1901 Census, the family lived at Annery Kilns, Monkleigh. Eliza and Henry Hopkins married 2 July 1911 in the United Methodist Church, Bideford

Harry and Eliza had four children – my Dad was the oldest, and born in 1911 (1912), Ernie was next (1914) (Rob’s dad), then came Mary (1917) and Frank (1915), My Mum used to recall how my Dad, Phillip, used to take a pony and trap to Clovelly (7 miles from Bideford) to collect the herrings. Cousin Rob recalls his Dad doing the same. Mum also recalls that Harry Hopkins owned gravel barges, collecting sand at Braunton in the estuary, and two men would take the unladen boat downstream at the turn of high tide, and beach it. Once the tide had receded, the two men would load about 10 ton of sand manually throwing it up into the barge. As the boat lifted, laden, off the beach, it would sail up to Bideford and unload at high tide manually. It must have been terribly hard labour as the tide turned and the Quay became higher and higher - especially after spending 11 hours loading earlier in the day!

In the 1921 Census, Henry (publican) and Eliza Hopkins are living in the New Ring O Bells, 7 Honestone Street, with Philip, Ernie, Frank, Mary, Henry Major (nephew), Florence Major (niece) and Kate Evans (boarder)

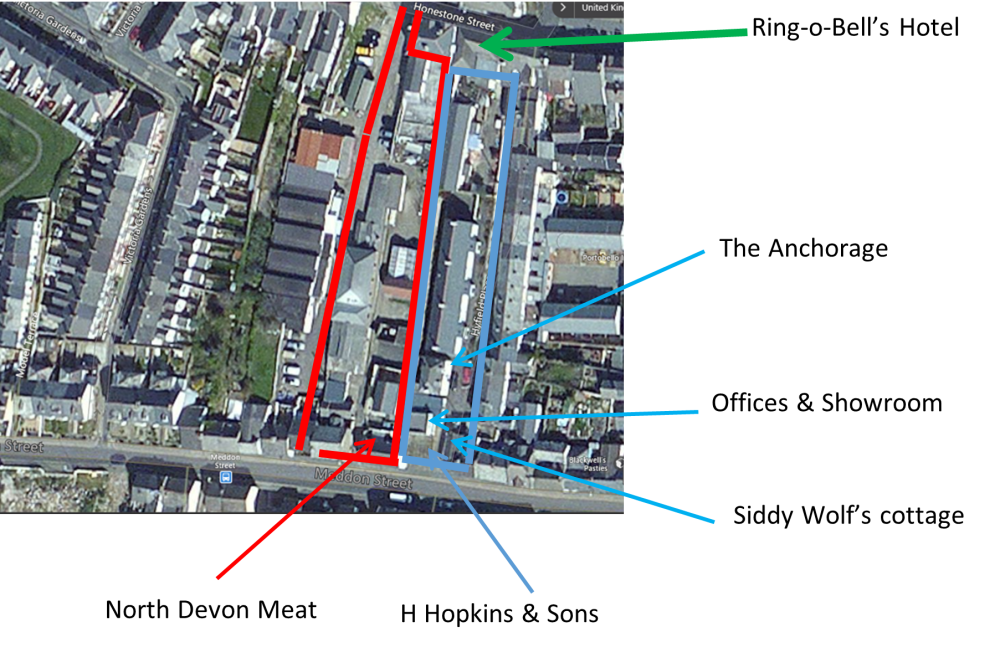

The dairy had access to Meddon Street and Honestone Street and in 1939, Harry built a detached home “The Anchorage” at the Meddon Street end but I cannot find any record of any lorries being involved before the first new lorry in 1943. However, he left his estate to the four children with a proviso that they would jointly care for Gran Hopkins for the rest of her life.

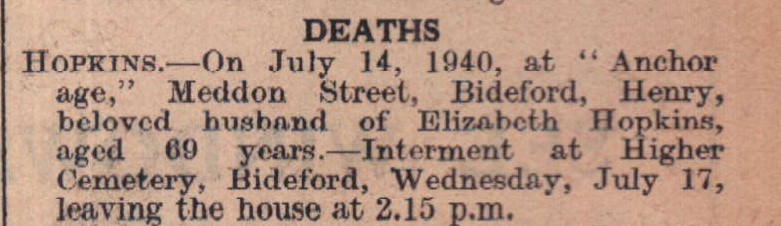

The 1939 Register details Henry Hopkins, a master haulage contractor, living at the Anchorage in Meddon Street, with Elizabeth (his wife), Frank (lorry driver assisting father, cabinet maker and carpenter), and Barbara (chief accountant, furnishers and house agent). Henry Hopkins died 14 July 1940, age 60

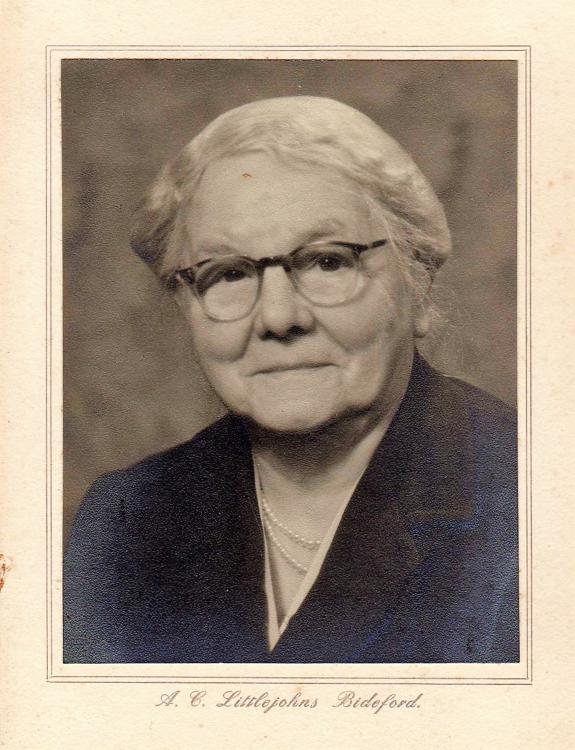

Gran (Eliza) Hopkins (nee Shears) was at the centre of the family and typically Victorian - she died in 1964, age 86

My Dad was married to Marjorie in 1937 and moved to a new terraced house in Royston Road (cost was £508); and Ernie was married to Renee, and left home to live in Elmdale Road. When my Grandad died, Frank and his wife Phyllis were living at the “Anchorage”, with Mary (who never married), and with Gran Hopkins. My dad trained as an Accountant/Book-keeper, and was working for North Devon Farmers in Bideford; Rob’s Dad, Ernie, trained as mechanic working for the Southern National Bus Company in Bideford; Frank trained as a Cabinet Maker and Auntie Mary as a Book-keeper. I am not sure when the company H. Hopkins & Sons was created, but when Harry Hopkins (my Grandad) died in 1944 (1940), it became a partnership of the 4 children. Uncle Ernie set up his own car repair business and got the Agency to market Standard & Triumph cars, as a sub-Agent to County Garage in Barnstaple; Rob also did his training to become a garage mechanic at County Garage; Uncle Frank started building the transport business and was good at building lorry bodies; and Aunty Mary did the accounting for the business. Uncle Frank and Aunty Phyllis lived in the left half of the house, and Gran and Aunty Mary in the right half. At the time that Grandad’s assets were transferred, my Dad was doing very well as an accountant at North Devon Farmers, and wanted to progress his career there. When he came back from the war in 1946, he was promoted to Manager at the Barnstaple Branch of North Devon Farmers and gave up his rights to the assets and became a “Sleeping Partner” to H Hopkins and Sons, with the two operating wings - Hopkins Transport & Hopkins Garage.

The 1939 Register records Philip and Marjorie (nee Tanton) Hopkins living at 52 Royston Terrace, Bideford.

the birth of Brian Hopkins

the birth of Norman Hopkins

1962 advert for Hopkins Garage

In the late 1940’s, Uncle Frank had 3 lorries.

The 1st lorry was a new British CKD built Canadian (semi-forward control) Dodge Major 100a - 'JTA' - 6-tonner

British made Austin K3 3.0-tonner, ex-Army tipper (normal control)

Canadian made ex-Army Dodge D15 tipper 3.0-tonner (normal control)

The Canadian Dodge (assembled at Dodge, Kew) arrived from County Garage in Barnstaple with a ready-built cattle body and it had a completely demountable body so that it could easily be changed to a “Tipper”, with a mechanical tipping mechanism. I believe this vehicle was partially justified for building RAF Winkley Fighter Airfield in 1943/1944. The driver was Walter Ayres and I remember his vehicle collecting our own-reared pigs for the slaughter house from 1947 to the early 1950’s. Additionally, there was a Standard Vanguard car, which Uncle Frank used for towing his caravan and doing Taxi work – thus continuing my Grandad’s work in the “Model T Ford”.

Early Development of the Transport Business 1943 to 1957

Sometime after my Dad returned from the war in India, Uncle Frank made my Dad a beach hut located at Taylor’s Field in Westward Ho! and during the FA Cup Final in on 1st May 1954, when West Bromwich Albion played Preston North End, we all listened to it on the radio as we worked - West Brom won 3-2. Walter Ayres, using “JTA”, helped my Dad move the beach hut from Taylor’s Field to a new site owned by Mr Wylie at the Bath Hotel in Westward Ho! I remember my brother Brian driving this vehicle in the late 1950’s, taking sand from the Woolaways Dredger at Bideford Quay to the their Depot at Holsworthy. Also, I remember my Dad borrowing the Austin K3 to collect tree trunks from Westward Ho! and returning them to the Scout hut in 1951 where, over a few weeks, we cut them up into logs and delivered them to the old folk of Bideford in the same truck. My Dad served in the REME during the war and was very familiar with driving this type of lorry.

In the early 1950’s the property below “The Anchorage” was demolished to build a 2-storey building and I remember the old ex-Army 3.0-tonners being loaded to take away the rubble. The lower floor became a car showroom, and the upper storey was used as the company office; there was also a forecourt with 3 petrol pumps – I remember selling BP petrol there at 4s 8d per gallon. There was 2 star, 4 star and halfway octane 3 star petrol – a nice bit of pocket money during the summer holidays!

The next new lorry in 1949 (“LOD“) was the all-British made “100-Series” Semi-forward control 6-tonner. It had a semi-forward control cab with a lot of common components with the Leyland Comet and Ford Thames Trader cab (all made by Motor Panels). This was a tipper with the same bodywork structure as “JTA”. This lorry started off with the same Canadian petrol engine as “JTA” but not long after it was purchased, Perkins offered an alternative P6 diesel engine, which directly interchanged with the original Canadian V8 petrol engine, and was much cheaper to run.

'LOD'

The next new lorry in 1952 (“PTT“) was another “100-Series” with a longer wheelbase than “LOD” and without a tipper. It came with the P6 engine as standard and had the same cattle body construction, and could be dismantled to a flat-bed for timber collection from the boats, or for farm deliveries. The driver for this vehicle was Siddy Wolf – he lived in the house at the end of the Hopkins properties and was always available for any rush or out-of-hours jobs. I remember going up with Siddy to the big Exmoor Market at Blackmore Gate. He worked with all the farmers until he got a full load. Siddy loved his drink, and when we began the deliveries to various farms, Siddy was quite jovial and we travelled around the country lanes at quite hair-raising speed. What I remember most that when we started into a bend the lorry was stable, but at half way round all the cattle would lose their footings and the lorry would suddenly lurch sideways – very scary - glad I was young then! I also recall being at the Anchorage on Christmas Day, when Uncle Frank received a phone call from the circus at Barnstaple requesting someone to pick up a lame elephant to take it to a vet in Bideford. Uncle Frank started negotiating about how expensive it would be to get a driver etc. Gran said – “You cannot do business on Christmas Day!”, and Auntie Mary chipping in firmly agreeing with Gran! The end result was that Uncle Frank agreed to do the job at no cost, driving “PTT” himself, because Siddy Wolf was in no fit state to drive!

The next new lorry in 1953 (“ROD 478“) was another “100-Series” with the same wheelbase as “PTT” and without tipper, and driven by Cyril. It came with the P6 engine as standard and had the same cattle body construction, but could be dismantled to a flat-bed for timber collection from the boats, or for farm deliveries. In 1955, Hopkins Garage purchased a Standard 10 5 Cwt Pick-up "TTA” which was intended to carry spares and collect parts for the garage repair work. It was soon converted to having a small pig truck body, with loading ramp for collecting and delivering pigs to the Bideford Slaughter House. I remember driving to South Zeal, near Okehampton to load 2 pigs (the maximum load) - pigs hate confined spaces, but fortunately, the farmer knew the secret of loading them, and I was soon underway back to Bideford. When I met Ann (my wife to be in 1963), I was allowed to use the pick-up to get to see Ann at Little Torrington – 8 miles away but Gran did not approve of me using it because it smelled and she knitted a seat cover for Ann to sit on to keep her clothes clean, and gave me an “Airwick” to freshen up the cab. It served its purpose.

'TTA'

The next new lorry in 1955 (“TTT“) was another “100-Series” with the same wheelbase as “PTT” and without tipper. It came with the P6 engine as standard and had the same cattle body construction, and could be dismantled to a flat-bed for timber collection from the boats, or for farm deliveries. With the Slaughterhouse Contract growing, although “TTT” had the same structure as LOD, PTT and ROD, “TTT” was converted to a fixed Cattle Body with a Box over the cab, allowing the ability to carry more sheet or pigs. “Wilfy” was the new driver employed to drive this vehicle. When flat-beds were required, LOD, PTT and ROD were generally used, for unloading the timber boats, but JTA & LOD were also available as Tippers. The next lorry in 1956 (“UOD“) was another “100-Series” with a short wheelbase as a 6-ton tipper with hydraulic tipping gear and it came with the P6 engine as standard. It was specifically ordered to replace “JTA” but it was initially contracted on site to build Yelland Power Station. Walter Ayres was promoted to the driver of “UOD”, but “JTA” actually soldiered on for several more years, and replaced with “UHT” an identical second-hand tipper to “UOD” in the late 1950’s.

'UOD'

In 1956 a Humber Hawk “UOD 10” was bought which was used as a taxi to replace the earlier Standard Vanguard. It was a relatively large car and was ideal for Uncle Frank to use it to tow his caravan (which weighed over a ton). One day, whilst bringing the caravan back from Taylor’s Field at Westward Ho, I got halfway up Torridge Hill, ready to make a sharp left turn into Meddon Street, when the gear lever jumped out of 2nd gear into Neutral, and almost broke my wrist (the gear lever was mounted on the steering column). The hand brake would not hold the combined load of car and caravan and started to roll-back. It was too steep to restart the car, but I could hold it on the foot brake. The driver behind realised I was in a predicament, and ran up to Hopkins Garage, and Uncle Frank came back with “LOD” and a heavy rope and after nearly half an hour of blocking the main A39 road through Bideford, traffic started moving again.

Humber Hawk 'UOD 10'

Uncle Frank's first long distance lorry, “A” licenced Lorry, was a 1956 Dodge 4-wheeler 100-Series 7-tonner “VOD 601” with a Perkins R6 diesel engine. It had larger tyres and the R6 developed 120 HP (20/30% more than the P6). It also had an Eaton Two-speed axle and combined with the 5-speed gearbox, it effectively had 10 gears – very useful over Devon’s hills. It had no tipping gear in order to keep the unladen weight to a minimum. Based on contracts with Bowyers at Trowbridge, and Harris’s at Calne, Uncle Frank built a full aluminium bodied cattle truck to carry pigs from the Bideford area to the two factories in Wiltshire (Trowbridge & Calne). As a flatbed with aluminium body, it could easily be modified to either a flatbed or with short sides retain the opportunity to be a light unladen chassis (enabling maximum payload of around 10 tons). It proved to be somewhat unreliable because of the R6 con-rod failures, which in the hilly terrain between Bideford and South Wales involved descending a lot of hills. Wilfy, the only long distance driver, got frustrated with the vehicle constantly breaking down. He broke down at the bottom of Black Cat Hill, near Bampton with a total engine failure and, on another occasion, on the way from Gloucester on the A48, to Cardiff, the engine seized near Lydney, on the A48, and the entire drive axle was ripped off its mountings.

When the next new vehicle arrived, Wilfy gave up the Dodge and became lead driver with a new wagon and Taffy became the new driver. I remember going to Stoke-on-Trent with Taffy to deliver china clay from Peter’s Marland to Stoke-on-Trent and going up the hills took forever - I remember it took us 30 minutes to climb up over Red Hill, just before Bristol Airport. When we got to Bristol, we stopped to watch Bristol City play football and then proceeded north of Bristol and parked in a transport cafe for the night - out with the sleeping bags. It was illegal for the driver to sleep in the cab in those days, but Taffy had good relations with all the transport café’s he visited. The café proprietors looked after their drivers, and Taffy never had a visit from a policeman! Eventually, when we got to Stoke, we had to shovel the whole 10 tons off the lorry by hand. The next day, we drove to Birmingham to collect some steel cable for Cardiff, which was off-loaded, and then we drove to a colliery to collect a load of coal. We spent the night there, and next morning we drove home to Bideford. This was before the Severn Bridge was opened, and we had to drive up to Gloucester and then back to Bristol and home. It was over 12 hours to get back from Cardiff. The following day, we drove to Littlejohn’s Coal Merchant and off-loaded 10 tons of coal by hand. It was a busy but exciting week. My next memory of “VOD” was when Topher Gibbs and I were invited to go to Great Malvern for a week - we had our bikes tied down onto the two lorries, and I travelled with Taffy in the front lorry, with Topher and Johnny following in “XDV Dodge”. We stopped at the transport café at Hill Common, just before Taunton – where all the drivers stopped, and had a bacon sandwich. We then travelled on up over Redhill and on to Bristol where we had to wait for the Cumberland Swing Bridge to allow a sea freighter to pass through, and then up over Bridge Valley Road, which was low ratio crawler gear all the way up out of the Gorge. Eventually, we stopped at the Brittania Transport Café near Filton, on the north side of Bristol, and enjoyed egg and chips – the like of which I have not had since - it was gorgeous. Johnny complained that “VOD” was too slow, and he did not like hanging behind. Eventually, we were dropped off on the A38, late afternoon, and cycled into Great Malvern, where we pitched our tent in the friend’s garden.

My involvement and Interest from 1957

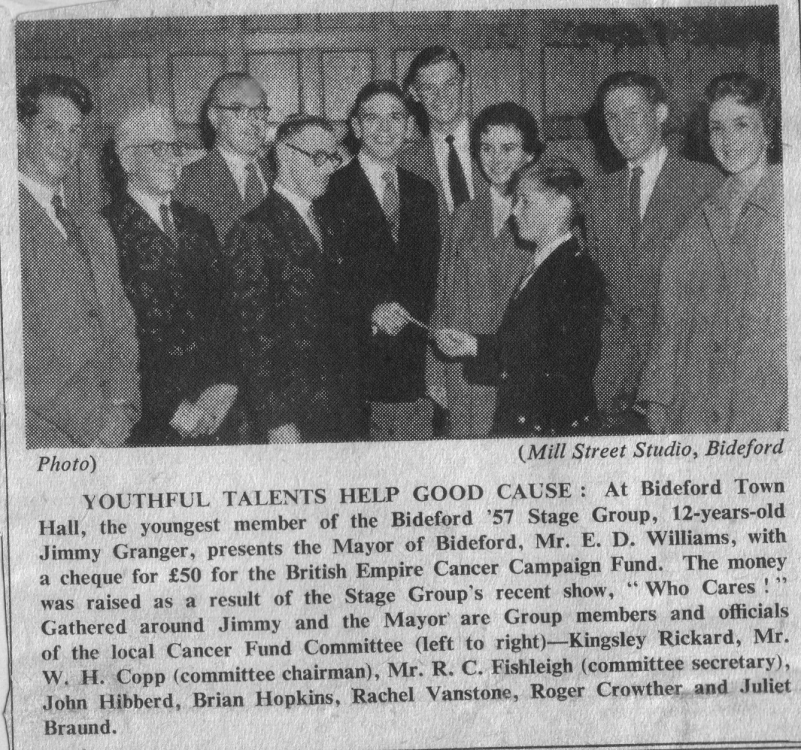

There was a little matter of leaving school. That sounds simple enough but a group decided that we should get together with some maids and fellas from other schools, who were also leaving and we formed the ‘57 Stage Group. This group comprised Juliet Braund, Andrew Cox, John Hibberd, Jimmy Grainger, Ann Pooley, Marian Jones, Jill Rogers, Roger Crowther, John Morgan, Roger Fishleigh, Kieth Lee, Brian Hopkins and Kingsley Rickard. We were also assisted by Rachel Vanstone, Kenny Day, Bob Ivory, Dick Bain and Judith Cox. The ’57 Stage Group presented “Who Cares” (A Summer Show for the Whole Family) at Instow, Bideford, Merton, Hartland and Westward Ho! at the end of August. The programme cost was 2/6 and all was in aid of The British Empire Cancer Campaign. At the end of the week we presented the Mayor of Bideford with a cheque for £50. The show was well supported, and enjoyed, by the public and it was well reported in the Bideford Gazette and the North Devon Journal. The two correspondents offered some constructive criticisms to the group but they did not realise that the ’57 Stage Group would never be seen together again because most of the group were of the age when it was necessary to leave Bideford to make progress somewhere else in the world.

My initial role with H Hopkins and Sons was to carry on where Brian left off, and serving petrol at the garage pumps. Being on the only main road to North Cornwall, summer traffic was exceedingly heavy and it would not be unusual to have a 6-mile queue waiting to cross the only bridge. Our petrol station was the first they came across on the A39 after the Bridge, and it was very hectic from 8.00am to 7.00 pm in the high season. My second challenge was to be responsible for loading the lorries when a coal boat came in to unload. Bideford Town Council had just purchased a new Ruston Bucyrus crane to unload the boats and my job was to issue a ticket to the driver for each load. I was supposed to ensure that each lorry was loaded the same for each trip, but I was only 14 years old, and the crane driver took this on board. What had to happen was that for every fifth load, each driver had to drive over to the Harbour Weighbridge to get his load weighed – each lorry had previously been weighed unladen. However many tickets each driver received, the average of the fifth loads were used to pay the haulier. If the coal was for Bideford, only 4 lorries would be used. For the Barnstaple deliveries, 7 or 8 lorries would be used. In those days, Uncle Frank had 3 Tippers “JTA***”, “LOD***”,”UOD***”". He worked with the Harbourmaster to know when boats were due and his Operating Licences enabled him to contract-in other hauliers. There was a tipper from Bartlett’s Timber merchants (a Bedford Mighty Giant), another from Notts Quarries (a Thornycroft), and another which was from, I believe, a builder (a Dennis Pax). There must have been others, because in summer, the Barnstaple trip could take 11/2 hours. I cannot recall who, it was a long time ago. On fifth loads, the drivers would try to cheat to and request more coal, and if the crane driver could be persuaded, it would happen. On one occasion, I was busy minding my own business, when a policeman walked up to me and asked “Are you in charge here?” I sheepishly replied “Well I suppose so” but he did not like my response, and told me to “Pick up your broom and shovel, and come with me to the end of the bridge and see the mess!”. As the well laden lorries turned left to cross the bridge, there was a heavy trail of coal spilled onto the road. The lorries were long gone, but the policeman stopped the traffic in both directions whilst I swept up many hundredweights of coal onto the pavement. It took probably about half an hour to clear the road. Then he said – “You can’t leave that on the pavement – move it lad”. When I got back to work on the loading, the crane driver was in fits of laughter, and when I told Uncle Frank about it, he burst into laughter also. From that point on, the crane driver was given the responsibility of not overloading! – no more arguments with policemen or drivers.

When the boats were not in, I started helping Uncle Frank to repair the lorry bodywork (because he had trained as a cabinet maker, and he knew I loved working with wood). We worked together every Saturday, and I recall Gran wandering up the yard with two mugs of tea on a tray. It was noted by everyone who knew her that the kettle was always on the boil, and a hot teapot was in the hearth. One of my early projects was when Uncle Frank said that Gran wants a new teapot stand – can you make one for her? – by the end of the afternoon, Gran was well pleased.

1957 - the deregulation of Road Transport

Up until 1957, there were 3 types of licensing for lorries - this was introduced in 1949 by the labour Government after nationalising the railways, and restricting use of road transport. A "C" licence was for companies transporting their own products; and a "B" licence restricted two types of operation - Radius from the transport company, and/or product carried. There was one exception, which allowed a free hand to rural areas involved in transporting livestock, with no restrictions, and the other permitted activity was to allow cattle trucks to get involved in other transportation. Uncle Frank got a contract to deliver all cattle for the slaughter to Bideford Slaughter House, which was next door. When I became involved, he had 4 lorries which had the ability to be changed from Cattle bodies to flat beds and 2 had tipping gear, which were used to transport coal, coke and timber from Bideford Quay. The other licence was "A", which allowed any haulier to carry goods anywhere in the country - these were hard to get, and the majority of "A" licences were held by British Road Services (also owned by the Labour government). With the Conservative government in 1951, this changed progressively, until in 1957, the law changed to allow anybody to carry anything anywhere and this led to an explosion of new, heavier vehicles, and the beginning of massive losses for the British Railways Network, culminating in the Beeching Axe in 1961.

In 1955, during the National Rail Strike, lorries were used to move goods from the Railway Yards to the planned destinations which was a lucrative business to anybody with lorries! Uncle Frank collected material from Plymouth, Exeter and Newton Abbott using his “B” licenced vehicles. However, on Christmas Eve 1955, Uncle Frank arrived at our home with a package wrapped in Christmas Paper and when Dad opened it, he discovered that the contents was a total of 22 Summonses for illegal operation of the trucks during the Rail Strike. They were issued in the names of all 4 partners, including my Dad who was most unhappy because he was only a “Sleeping Partner”. When he discussed it, Uncle Frank said “Don’t worry about it, we are more than covered by the profit we have made!” I never heard anything further on this.

The next new vehicle was in 1957 - a Commer with a TS 3 (3 cylinder twin opposed) 2-stroke blown Diesel Engine “XDV 177” and became known as “XDV Commer”. This proved substantially more reliable and returned 16 MPG compared with the Perkins returning 12 MPG. With a new vehicle in the fleet, and Wilfy’s dislike of “VOD 601” he became the senior driver and took over the Commer. A new driver, Taffy, took over “VOD”.

XDV Commer

The next new vehicle was in 1958 - a Dodge 7-ton (normal control) with a Leyland Engine (good riddance to Perkins R6) and became known as “XDV Dodge”. Johnny was the new driver for this vehicle, but he was always getting himself into scrapes. In those days, once the local traffic authority agreed to a company adding a truck, there was an understanding that after 12 months, it could be modified to add a Third Axle to increase the payload. This proved a more reliable vehicle, and was converted into a 6-wheeler by Boy’s Axles in the Midlands allowing a maximum GVW of 20 tons. Johnny was always fun to work with, but when he arrived back one Saturday morning, he reported that his spare wheel had been stolen. Eventually, it became obvious that he had sold it! There were two outcomes to this event. Because the ability to repair punctures on the road had become easily available, Uncle Frank decided it was much cheaper to have tyre problems sorted out on the road, and increase the payload than to run with a spare. The second was that Johnny disappeared, and nobody quite knows what happened to him.

XDV Dodge

The next new vehicle was in 1959 - a Commer with a TS 3 (3 cylinder twin opposed) 2-stroke blown Diesel Engine “--- EUO” which proved reliable, and returned 16 MPG compared with the Perkins returning 12 MPG. After 12 months, it was also converted to a 6-Wheeler using a Primrose Third Axle conversion. John Denford became the new driver for this vehicle.

'EUO'

Converted by Primrose Axles to 6-wheeler in 1960

I recall driving home from Chippenham in 1965, and coming up over the hill from Black Cat, there is an old quarry on the side of the road and as I approached, I found “EUO” parked up. I stopped and asked John what was up and he said the crankshaft has broken, and it has just happened. I drove back to Bampton and got John’s flask refilled with tea and a couple of bacon sandwiches from The Wishing Well Cafe which John very much appreciated that when I got back. We were sat in the cab as he tucked into his sandwiches whilst we were wondering what to do next, when I heard the sound of a Gardner engine climbing up the hill laden, with the ERF “KTA”. I jumped out of the cab, and waved Wilfy down, who stopped, reversed into the quarry, retrieved a towbar from the cab and in a few minutes he pulled away with John sat in “EUO” and proceeded homeward. John was fully laden, and so was Wilfy, but the ERF took it in its stride.

'KTA'

In early 1961, “VOD 601” had its final failure somewhere near Jubilee Inn, between Bampton & South Molton - Uncle Frank called me at about 7pm on Friday night to say that “VOD” had broken down, and the load had to be delivered to Mole Mill in South Molton. Siddy Wolf had already been sent out in the cattle truck to initiate transferring the load, and Siddy and Taffy transferred half the load to “PTT”. By the time Uncle Frank and myself arrived at Mole Mill in the cattle truck “ROD 478”, Siddy had just arrived back with the first half of the load, and he took over “ROD”, went back to load the other half, and Uncle Frank and I stayed at Mole Mill to offload “PTT”. We had just finished offloading PTT when ROD arrived back, and Siddy was sent back with PTT to tow VOD back to Bideford. It was well after midnight when we all got back to the Anchorage, and we were tired. Auntie Phil cooked fried egg sandwiches for everyone – something I will remember for ever.

In 1960, Uncle Frank purchased a second-hand Seddon Diesel with Forward Control cab. It was registered original in Liverpool “PLV 600” in 1957.

'PLV 600'

The cattle body from “VOD 601” was altered to a fixed body and transferred to “PLV 600” which meant that the Seddon with the more reliable Perkins P6 engine could only be used for animal transport. This was ideal because the contracts to take pigs to the pork factories of Bowyers in Trowbridge and Harris’s in Calne became reliable - two trips a week kept the driver Gareth fully occupied. Later, he used to go to Avonmouth, from Calne or Trowbridge, to load up with Silcox Feedstuffs. Because the body had been designed for “VOD”, it was about 18 inches longer than “PLV” but Gareth liked this because the extra overhang took load off the front axle and the steering was so much lighter. None of the lorries had power steering in those days. Gareth was a new driver, and on one occasion, he pulled into a fuel station, near Glastonbury, forgetting that the vehicle was high bodied and completely demolished the canopy over the pumps. It took a lot of effort to rebuild the box over the cab too! Eventually, the Avonmouth run was abandoned because the loaders at Avonmouth found it too tedious to load from the back of a cattle truck. However, for a couple of trips, Gareth tried taking the sides off and stacking them on the lorry bed and then loading the Silcox bags on top which proved time consuming and raised the centre of gravity so high that it became very unstable to drive. The chassis-cab Dodge “VOD 601” was taken to Newton Abbott to have a tipper body fitted and would be used only on limited journeys. It was always used for offloading coal and timber from the boats, working within a 9 mile radius and, additionally, it did almost daily trips between Exeter Gas Works and Bideford Gas Works (no serious hills on this route) carrying coke. The lorry sides were extended by about 12 inches because the coke was much lighter than coal. Eventually, Perkins made good the engine, and it became a very reliable vehicle. Another journey I did was a trip to Torquay, with Uncle Frank driving, to take the Bideford Reds boats to the Torquay Regatta – probably in 1961.

The next new vehicle was a BMC J2 11-seater Minibus “HDV”. Uncle Ernie was Chairman of Bideford Town Football Club (“The Robbins”) and as a true Hopkins entrepreneur, he purchased it to take the eleven players (+himself) to away matches.

'HDV'

It was also used as a general run-about and taxi service during the week and on Sunday’s, I had the privilege of driving it to collect all the children for Sunday School at Bridge Street Methodist Church. My Mum had insisted that we would all be Church of England, but my Gran was not happy because she wanted us to be Methodists. Mum won, because her father was the head gardner at the C of E Rectory, although Auntie Mary was the Methodist preacher. Invariably, when I got the children to the Sunday School, something always happened to make me late, and I always had to race down the hill to St. Mary’s Church – usualy after the service had started. Gran must have had a hand in this, but I was never able to confirm it!

The next lorry was a second-hand Dodge Tipper (identical to “UOD'). It was registered in Bristol in 1956 and 'UHT'' arrived in 1961 and was probably purchased to replace 'LOD' which was kept on a little longer because of additional work. By 1961, there were 10 lorries to park-up over a weekend - space was at a premium, and Uncle Frank wanted to dig away Gran’s garden to make room for another lorry. Gran, Auntie Mary and Auntie Phyllis got together to put a stop to that idea! At the same time, Uncle Frank and Uncle Ernie were planning to go up-market and start buying heavier duty, more reliable vehicles. In order to expand the business, Uncle Frank had always yearned for a warehousing facility and they purchased land behind Rhodian Tyres in New Road (at the bottom of Torridge Hill) but the area had to be opened up by cutting away a huge rock face at the rear. Woolaways were contracted to do the digging and loading of the trucks “JTA", ”LOD”, ”UOD" and “UHT” to haul away the many tons of spoil. The warehouse came as a precast set of concrete parts, Woolaways prepared the concrete forecourt, and Crendon Concrete assembled the Warehouse. No money changed hands with Woolaways because Uncle Frank worked off the debt using the same lorries to unload their sea dredger at Bideford Quay. The sand was delivered to Woolaways prime sites of Barnstaple (9 miles away) and Holsworthy (20 miles away). My brother Brian was old enough to drive a truck and he devoted his summer university break to driving “JTA” for almost the entire holiday. Eventually, towards the end of 1961, all the trucks were transferred to the new Hopkins Transport depot in New Road, and shortly after this, “JTA” was finally pensioned off.

new depot - 196N

Developing my Career

As I approached my “A” Levels, I really had no idea of which career to pursue. As a young lad, I wanted to be a steam-engine driver, but by the mid-1950’s, the railways were clearly in decline, so I decided I would like to get involved in coal mining with a desire to live in Newcastle. Then, I wanted to go into the Forestry Commission, and finally, I wanted to become an architect. In my final school year, the local job advisory service suggested I should become a mechanical engineer taking part in a 5-year training programme. I was invited for Interview in September 1960, and my Dad took me and we stayed overnight. On the first day we had a tour of the Westinghouse Brake & Signal Company factory, including the training facilities. Westinghouse made railway brake systems and signalling systems. On the following day, all the potential candidates were interviewed and I was offered a “student apprenticeship” with degree training in London, 6 months every year and training within the company for the rest of the year. Dad thought the opportunity was fantastic and encouraged me to take it seriously. He was very impressed by the training facilities (Fitting, Machining and Fabrication workshops). Sadly, my Dad died in May 1961, just before I took my “A” Levels, and when the results came through in August 1961, I had passed Physics with Distinction, but failed Maths & Chemistry, but was awarded a Merit for Technical Maths. My Headmaster wrote to Westinghouse and managed some miraculous recovery, and I received an offer for a “Technical Apprenticeship” which involved night school one whole day a week and night school two days a week to achieve a “Higher National Certificate in Mechanical Engineering”. Mum and I were very excited, and I quickly wrote to accept it, and I continued working at Hopkins over weekends to earn extra cash. In September 1961, I left home to start my apprenticeship at Westinghouse Brake and Signal Company in Chippenham, Wiltshire. At weekends, though, I was able to get a lift home and back with a colleague who was working for Bristol-Siddeley Aero-engines, and I was welcomed by Uncle Frank to work Saturdays (and I was paid 10-shillings - 50p in today’s money). This was a great help, because I only got £4-6-0 (£4.30 in today’s money) per week, which included £2-10-0 lodging allowance, which I had to pay my landlady. I also had to pay Jerry £1 as part of his car costs, to get home and back from Devon. When I met Ann, in 1963, I used to struggle to buy her favourite drinks at a dance because she loved “Babycham” and a “rum & black”. Eventually she realised my problem, and she agreed to share the cost of drinks. I could not have gone to dances with Ann had it not been for the help of Uncle Frank. When I finished my apprenticeship, there was no work at Chippenham - Westinghouse had been given a contract to fit brake systems to all British Railways freight stock. This had been poorly thought through, and the time delay across the train length created differing application times across the trucks which was caused by the fact that the freight trucks were not close-coupled (like passenger carriages). As a result of this and the Beeching Axe, this contract was cancelled. Westinghouse was well compensated, but work for the Chippenham plant was reduced. Instead of being offered a job at Chippenham (and I desperately wanted to be Foundry Manager), I was offered a job at the Kingswood Factory which made Air Brake Systems for lorries – Yippee!

Brian Hopkins and Juliet Anne Braund - 1963

the marriage of Norman Hopkins and Patricia Dolton

Products carried & getting the loads

The local lorries were organised on daily local trips basis. On the cattle trucks, the schedules were organised between Uncle Frank and North Devon meat (located next to Hopkins Garage). North Devon Meat required a regular flow, but accepted that the lorries may have to be released if a timber boat arrived at the Quay. JTA and LOD were tippers too, so they would be the first to be released and sometimes ROD and PTT. Off-loading a timber boat took around two days, so often additional cattle work was organised before and after timber boat work. Because PTT did regular market day touting for farmers to get their purchases home – Normally, Bideford on a Friday, and Blackmore Gate (on Exmoor) on a Tuesday

The prime traffic was - cattle, sheep & pigs to the slaughter house; coal from the Quay to Bideford & Barnstaple Gas works; Devon County Council road construction work; general distribution from the local Railway Goods Yard; sand & gravel deliveries from builders merchants; and concrete blocks from Bideford Concrete Works. The main objective was to get a load to take out of North Devon, for the “A” licensed vehicles, Ideally, to get the lorries off-loaded early on a Saturday morning, would enable the lorries to be loaded-up and back in the Depot late Saturday afternoon, and then be able to leave at around 5.00 am Monday morning. The pig traffic had to be loaded on the Monday morning. The prime loads to take out included - pigs from local pick-up points to factories in Calne and Trowbridge; tree trunks for the paper mill in Chepstow; pit props (tree trunks) for coal mines in Cardiff and Swansea; railway line from old railways in North Devon and Cornwall for Port Talbot; railway sleepers for the Midlands; china clay for Stoke on Trent; and Ambrosia Creamed Rice from Lifton to London. Uncle Frank would organise all this himself for the outward journey and he would try to organise a “back-load”, before the driver left home, but keep in touch with the “Clearing Houses” - of which there were many in the major towns. Uncle Frank would require the drivers to report in twice a day to confirm their locations and if he was able to get a “Back-Load”, the driver would be advised to go to the Clearing House, and organise loading. Sometimes, with the more reliable drivers, they would tie up a schedule. All the drivers were aware of the 'Golden Rule' - “More than 100 miles per week without a load meant that the lorry made no profit for the Week”. The biggest issue was to fill the week and end up at the normally pre-arranged load for returning to Bideford for Friday night. The prime loads to bring back were - coal from Cardiff to Littlejohns coal yard in Bideford; bagged salt from Sandbach Cheshire to North Devon Bakeries; animal feeding stuffs from Avonmouth to H Hopkins Warehouse; slag from the steel works at Scunthorpe to H Hopkins Warehouse; and copper pellets from Swansea for areas close to Bideford. Uncle Frank worried more about getting the back loads and getting the lorries back on time ready for next week’ loading than anything else. Getting loads back to North Devon was often difficult.

Problems caused by the explosion in Road Transport from 1957

Regulations were minimal. Drivers hours were not under control. Gross vehicle weights were not related to vehicle capability with Operators able to modify vehicles without regard for vehicle safety. Maximum Speed 30MPH (20MPH for 8-Wheeler) increased to 40MPH. Tyre failures caused by overloading and use of retreads. Drivers hours

In the 1950’s all heavy lorry drivers had to complete a Log Sheet covering all their activities on the road and they were limited to the hours they could drive before taking a break. The total number of days driving was limited to 8 hours, with the exception of 9 hours if they took a longer break overnight. The Log Sheet had to be completed at the start of work, and signed off at the end of the day. The Log Sheets were not sequentially numbered, and all drivers ran 2 sets of Log Sheets. If a driver coming from the opposite direction knew that there was a police check up ahead, they would wave their Log Sheets to the approaching lorry, and the driver would quickly pull over, and regularise his Log Sheet! Roadside checks seldom caught the drivers driving long hours, but the Ministry of Transport often recorded sightings of lorries on the road, and do spot checks at the Transport Depot. The fines imposed were minimal, and failed to discourage driving long hours. Ultimately, the Ministry of Transport issued Log Books with numbered sheets, although hauliers did find ways around this, but ignored the minimal penalties and regarded them as “Operating Costs”.

Gross vehicle weights were not related to vehicle capability and the basic rules in the 1950’s were - a 4-wheeled truck could operate at a maximum GVW of 14 tons; a 6-wheeled truck. a maximum GVW of 20 tons; and an 8-wheeled truck, at a maximum GVW of 24 tons. Essentially, there were 3 types of lorry manufacturers - light-weight chassis (Commer, Bedford TK, Ford Thames, Austin/Morris); medium-weight chassis (Dodge, Leyland, AEC, GUY, Seddon, Albion); heavy-weight chassis (Foden, ERF, Atkinson). To achieve maximum payload, most hauliers purchased the light-weight chassis, which had an unladen weight of around 4 tons which meant that the 4-wheeler could carry a payload of 10 tons (14 ton GVW). These vehicles were actually designed to carry 7 tons payload (11 tons GVW) but by adding the third axle, the vehicles were grossly overloaded (20 tons payload – nearly 100% over the design weight). As a result of this, there were many accidents and brake failures (brakes sized for 11 ton GVW chassis, operating at 20 ton GVW). Chassis failure was experienced by Hopkins Transport on “XDV Dodge" which arrived back at the depot one Saturday morning with Johnny complaining about steering problems. Uncle Ernie took a look and discovered that the right hand chassis member had completely severed just behind the cab. On another occasion, John Denford with “EUO” had a complete chassis failure just under the driver’s seat. Both vehicles were re-welded and flitch plates added by a specialist welder at Appledore. This was done before offloading the payload! “EUO” suffered a spate of engine and gearbox failures, due primarily to overloading.

During the early 1950’s the maximum speed permitted was 20MPH for lorries with unladen weights over 2.5 tons and in 1957, this was increased to 30MPH on all lorries, except 8-Wheelers, which were still limited to 20MPH. This increased to 40MPH in 1967 for all lorries. This limitation caused a lack of investment in UK engine design, however, there were moves ahead in Sweden in 1970, which changed all this, along with the expansion of the motorway system in the UK and joining the EEC – more about that later. In those days, there were no methods to check traffic speed – radar had not been adapted to speed trap applications. However, when the “Men from the Ministry” arrived one day to do spot checks on Log Sheets they advised Uncle Frank that the driver of Commer “XDV 177” (Wilfy’s waggon) was recorded as passing a specific place at Filton, north of Bristol at a specific time, and passed another point on Bedminster Downs at a later time. Calculations of time difference/distance covered showed that the average time between the 2 points represented an average speed of 40MPH. The speed limit through most of the area was 30MPH (all built-up areas limited to 30 MPH maximum). This was actually two months earlier. Whilst they were there, they also discovered some discrepancies with the Log Sheets - poor old Wilfy was not happy, but Uncle Frank was not too worried about it – again, these small on-costs could be easily covered.

Tyre problems - it was not uncommon to see the complete tread of a lorry tyre lying beside the highways and to save costs, vehicle operators were using cheap re-treaded tyres. The problem was that there were no regulations to control the process and the safety of the re-treaded tyre really relied on the quality of the carcase underneath. Soon retreads were banned. The other trick was a little machine designed to re-cut the tread depth which was a bit like an electric soldering iron, with a U-section heated cutter. The trick was to follow the groove form, with a guide on the cutter to prevent the blade going too deep. The objective was not to contact the canvas case underneath. Soon, re-cutting of tyres for cars and lorries was banned. Later, whilst working with the chief engineer at BMC (1968), I was told that no truck tyre was safe above 50MPH – they were all hand made, and balance and centrifugal forces caused failure! I assume, by now, that quality control of tyre production has improved multi-fold.

A re-think in Hopkins Transport Policy - because of all the problems with “VOD 601”, “XDV Dodge", and “EUO”, maintaining a service became unreliable and expensive. With the new depot and warehouse facility available, Uncle Frank entered into two specific storage and delivery contracts with the most significant contract with Silcox, to collect and store bagged animal feedstuffs from Avonmouth, and to deliver to local farms. The second contract was to collect bagged slag from Scunthorpe and deliver to local farms. The Silcox contract worked very well, and guaranteed return loads from Avonmouth every Friday. During the week the smaller lorries would do the deliveries and there was frantic off-loading work every Saturday of both slag and feedstuffs however the problem was that Scunthorpe produced slag each and every day of the week, but farmers only wanted slag (as a soil improver) during the autumn ploughing period. The result was that the warehouse was emptied of slag during September to January, but it arrived all year round, and at times it was only through close control that sufficient space was available for Silcox products. Uncle Frank bought an old farm tractor with a front bucket to lift the slag from lorry to an ever-higher pile but eventually, he bought a second-hand petrol engine elevator, and was able to stack to the height of the roof. Off-loading the slag was not an easy job. The bags had been filled with hot powdered slag and had travelled down to Bideford from Scunthorpe all day Thursday and Friday, and the bags were “red hot”. All the other drivers, Uncle Frank and myself, had a one-hundred-weight bag of slag dropped onto our shoulders from the lorry, and we had to run with the bag to put it on the elevator before our shoulders burned. It was a tremendous incentive for everyone to get the lorries unloaded quickly! I think this process is likely to be the initiation of my back problems later in life. Today, however, we have “Health & Safety” regulations.

The decision was taken to purchase the first ERF Vehicle which was a 6-wheeled 20 ton GVW Gardner 6-LW (90 bhp – max Revs 1250) engined vehicle “362 KTA” which was a single drive tandem axle. It arrived in November 1961. The only failure I recall was, when tipping coke at Bideford Gas Works, the drive lost traction, and broke a half-shaft - I remember seeing the result – the shaft had split axially the entire length, and the shaft had rotated 1 1/2 times as it split. This vehicle served well on the slag & feedstuff runs! One prime experience with this vehicle was to use a new oil “BP Viscostatic”, which proved so reliable, that when the engine was checked at 250,000 miles, the piston bores were only 0.003 inches larger than original. The engine was rebuilt with the original pistons, but with all-new piston rings, but because the engine was so big and heavy, the crankcase was cracked during removing it from the chassis. This was repaired by drilling and tapping a series of overlapping ¼ inch holes along the crack for approximately six inches. Threaded brass rod was screwed into the first hole, cut flush and dressed before the next hole was drilled. It was a job well done, and no problems ever occurred with this masterpiece of engineering. Soon after “362 KTA” Uncle Frank purchased a second-hand ERF 8-tonner (payload) “1 NAF” - this vehicle was rated for 14 ton GVW, and used a Gardner 5LW (5 cylinder) engine, with the same cab as “KTA”. It was registered new in 1961 by Richards & Osborne at Fraddon in Cornwall, and was purchased by Hopkins Transport in 1965.

"1 NAF"

The next vehicle was an 8-Wheeled ERF 8-Wheeler (commonly known as an 8-Legger) which was initially approved by the local “Carrier Licensing Authority as a 6-wheeled vehicle, but a legal loop-hole meant that if it arrived with 4 axles, the second steering axle could be removed to allow operating as a 6-wheeler, and replaced after 12 months. The 8-Wheeler arrived, “CDV 367C” with a full Westinghouse Air Braking system and a Gardner 6LX engine. It ran well, and the senior driver Wilfy took on driving it.

“CDV 367C”

Apart from an incident in the Depot, where a Dodge Tipper driver was charged to move it, fully laden, but did not realise that you have to wait for the compressor to charge the air tanks, before releasing the hand brake and unfortunately, it rolled down the slope and smashed into “PTT” cattle truck. Being a glass-fibre cab, it did little damage to “PTT”, but seriously cracked the front panel of “CDV” on the near-side. Uncle Frank and I worked to do a quick fibreglass repair job, and a quick paint job to have it ready for Wilfy to drive on Monday morning. It did not look too tidy, and Uncle Frank would not divulge Wilfy’s comments - “choice words” - on the Monday morning. Eventually the correct replacement panels were obtained and the vehicle was restored to its original glory! The only other recorded incident was when the cab caught fire on the Portway between Avonmouth and Bristol after loading Silcox Feedstuffs bound for Bideford - the cab was totally destroyed, and the vehicle was taken back to ERF for full repair and respray. At around this time, ERF were reporting many fires on the same cab design and as a result of some devious research, it became known that drivers got fed up with the noise made by the Air Pressure Low Warning Buzzer. Rather than wait until the air tanks were up to a safe pressure (60 psi), before the buzzer went off, the drivers were placing a piece of aluminium foil between the contacts of the buzzer to prevent it working, and waiting a shorter time for a lower gauge pressure before starting to move the vehicle. Research at Westinghouse Bristol confirmed that short circuiting the buzzer would cause it to overheat, catch fire and set the fibre glass cab on fire. I did find two other ERF Tractors in our fleet, at a later date, that had been silenced using the “fag packet disaster” as ERF called it.

The next new vehicle was a Dodge 7 tonner (payload) which was specifically purchased in 1963 to be short and with narrow body and short overhang at the rear for delivering Silcox feedstuffs to farms. It had the latest fully forward control cab, using a variant of the cab used by Leyland and Albion known as the LAD cab. The Registration was “CUO ***C” and was fitted with a Perkins P6 engine - the bodywork was a non-tipper, and built with timber sides and tailgate. It also had an apex ridge running from front to rear to make loading and unloading easier, with a canvas tarpaulin, and it carried a logo board on the cab roof advertising Silcox Farm Feeds.

"CUO"

The next new vehicle was the first vehicle purchased that was designed to meet the proposed vehicle regulations “Construction & Use Regulations 1964” which was a 16 ton 4-wheeled vehicle designed for a 10 ton Payload “ETT 519C” and was purchased in 1963. It had a Gardner 6LW engine and was run at 16 tons before the actual Regulations came into effect.

“ETT 519C”

As the motorway system began to be constructed, the ability to exceed the 40MPH speed limit was still not fully effective, and the early 1964 Regulations were not designed for higher speeds. The only real problem this vehicle had was that the front axle brake linings were only 4 inches wide, and with brake performance required to achieve 0.5 g deceleration, lining life was very short. I remember this ERF coming into the depot with poor front brakes, and the reason was that the linings were down to the rivets - this had also made grooves in the brake drums. The nearest ERF stockist was at Frank Tucker Exeter (40 miles away), and a new brake drum was not available, so the new linings were fitted and the damaged drums re-fitted. The next Saturday, the new drums had arrived, but by then the linings were badly damaged, so the new drums were fitted with the worn linings. Two weeks later, new drums and linings were fitted. Dynmamic braking at 0.5g deceleration shifts so much load from the rear axle to the front axle, and that was the cause of the problem. Most vehicle manufacturers had this problem and lining widths were increased to 8 inches, the same and the rear brakes. Lining wear was checked weekly and the linings were replaced before drum damage occurred. The only other incident I can recall with this vehicle was when climbing up the hill beyond the famous Black Cat Hill, en-route to Taunton, the road got narrow, and “ETT” pulled over to allow another truck coming down. The edge of the road gave way, and the truck fell over the edge and rolled over and over before ending at the bottom of the field with the cab completely shattered. The driver was badly hurt and never drove a truck again, and this one went to ERF for a re-build and had larger front brakes fitted.

Construction & Use Regulations 1964

With all of the problems on the roads, especially with brake failures (no disc brakes in those days), along with all the other failures causing accidents, the Government introduced the 1964 Construction and Use Regulations. These regulations insisted on control of tyre size, dual system braking systems and a separate auxiliary brake control, and specific design “Factors of Safety” for steering and brake components. As a result of this, the permitted Maximum GVW’s were increased to: 2-axled Rigid 16 tons; 3-axled Rigid 22 tons; 4-axled Rigid 28 tons; 4-axled Artic 32 tons. Whilst the UK was busy developing the new 1964 C&U Regulations, when we were not in the EEC, the Germans took the lead to rationalise braking systems across the EEC. The new 1964 UK Regulations were ignored, and in 1971, when we did join the EEC, we had to change all our special safety systems to rationalise with the Germans. It was impossible to use an English tractor with a continental trailer, and vice versa. The end of the UK lorry industry was to be destroyed. Scania, in Sweden, was part of EFTA (as we were), but with the huge distances involved with road haulage, and the use of road trains (6-wheeled lorry + two 6-wheeled drawbar trailers), Scania decided to develop a 240 bhp engine which was very reliable and economical engine. Also, Scania’a cabs were larger, more comfortable, and a lot quieter with tilt cabs and sleeping bunks. Volvo soon followed this lead, and with the already extensive Autobahn systems across Europe (thanks to Hitler), Italy and the UK became the initial market for Scania & Volvo. At this time, the most powerful British engine was about 150 bhp (although Gardner did introduce a straight 8 engine rated at 200 bhp). This was unsuccessful because of the length of engine protruding behind the cab and the heavy weight of an un-turbocharged engine. However, the EEC decided to insist that there had to be a minimum of 6.5 bhp per ton, and both Leyland and AEC tried to rapidly manufacture and offer engines of 240bhp, in the Leyland 680 engine and the AEC 760 V8 engines. Reliability was so poor because of the time to test the prototypes, that the engines were dropped. This took away the Gardner and Perkins markets, and the lighter vehicle manufactures limited their production to 12 & 13 ton vehicles. Around the mid-1970’s, Daimler Benz and MAN joined in the take-over of the UK heavy market. The likes of ERF, Atkinson Foden and Scammell could only get UK assembled US Cummins engines. Later Caterpillar joined in to supply Foden. The net outcome of all of this is that the UK manufacturers produced only 15,000 lorries in 2011, compared with 199,000 in 1969 (UK then produced more lorries than any other European country). Today, we have no UK companies producing trucks in the UK.

The next vehicle was a Commer 30cwt van which was painted green with yellow sign-writing. It was second-hand, and specifically purchased in 1965 to collect spares from the Frank Tucker ERF Agency at Exeter (the 5cwt Standard 10 not man enough) and to go out and do limited repair work for any of the lorries.

Commer van

The next vehicle was a Tipper to expand the fleet, and was an Albion Chieftain 7-tonner originally registered in 1957, which Uncle Frank purchased in 1964 from the Leyland Agent in Taunton. It had a 4-cylinder Albion engine and an all-steel tipper body. It used the LAD cab and Albion Logo. Very soon after purchase, the gearbox had to be replaced, and soon after, the engine had to be rebuilt – not, after all, a good purchase.

Albion Chieftain

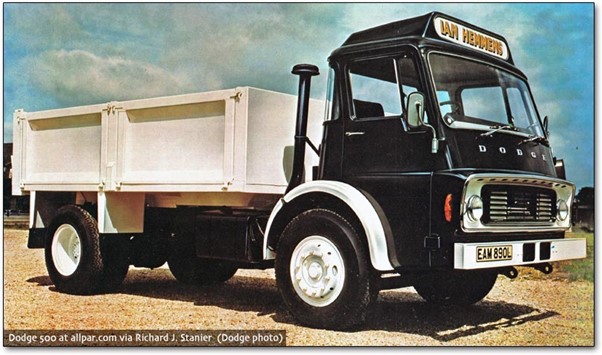

The next new vehicle was in 1966, a Dodge 500 (K Series). It was a fully approved C&U 1964 chassis rated at 16 Tons fitted with the latest Perkins T6.354 engine and was a medium wheel based tipper, and used for both long distance and local work. I cannot recall any major difficulties with this vehicle, apart from Uncle Frank calling me at home in Frampton Cotterell one Friday night to tell me that John Denford had broken down just south of Bristol. I went to collect John and determined that the throttle linkage had broken. John came back and stayed the night with us and next morning, we went to the Dodge stockist, got the rod we needed, went back to Churchill and successfully completed the repair.

Tipper Dodge - K Series

The next new vehicle was in 1969, when Silcox wanted Uncle Frank to run a bulk delivery service from Avonmouth to specific accessible, farms. At this time, the British truck industry was struggling to produce enough trucks, and Hopkins Transport wanted an ERF 6-wheeler, but delivery could not be achieved inside 6 months. Eventually, an AEC 6-wheeled Mercury was available within a month and it arrived with a high sided bulk tipping body and with the AEC AV505 engine. AEC was already owned by Leyland and AEC fitted the latest Ergonomic cab (same as Leyland), but carried the AEC Logo Badge.

AEC 6-wheeled Mercury

The final two vehicles I remember were around 1972. They were purchased second-hand in 1972, and probably initially registered at Stoke-on-Trent in1958. Both carried the registration “CVT” (ref.LA12). They were 6-ton ERF medium Wheelbase with Gardner (4 Cylinder) 4LW engines. They were purchased to replace the Cattle Trucks “PTT” and “ROD”. The bodies were lifted off complete with the flatbed, and modified to be simple permanent boxes that could be lifted off on gantries to enable the vehicles to be used as flatbed, for work for timber boats.

"CVT"

Beyond that there were several ERF tractors bought second-hand and 2-axled semi-trailers with Cummins NH engines but I am not sure of the detail after around 1972. In 1978, the decision was taken that all the Partners would retire, and Rob would take over the garage business, and the transport was sold to Evans Transport in Barnstaple. The new Depot in New Road now belongs to a heavy equipment digger/bulldozer hire company – called Clarkes.

When I got married in September 1966, Ann and I went to Hanover for 6 months, losing total contact with Hopkins Transport until June 1967, and we purchased our first home in Frampton Cotterell, north of Bristol. John Denford collected various furniture from my Mum’s and Ann’s Mum’s houses, and delivered them to our new home in Frampton Cotterell in “NAF”. By 1969, Mark and Rachel had arrived and we could only come back to Bideford occasionally. When we did, Mark and I always went to see Uncle Frank at New Road, and Mark loved climbing into the cabs, and watching the lorries being loaded and unloaded on the Quay. Finally, in 1975, we went to live in Cleveland, Ohio for a year, and lost further contact. The business was sold in 1978, and Frank, Ernie and Mary retired.

Philip Hopkins died 1961; Ernest Hopkins died 1987; Frank Hopkins died 1990; and Barbara Mary Hopkins, 1991